>Through-Hole Systems

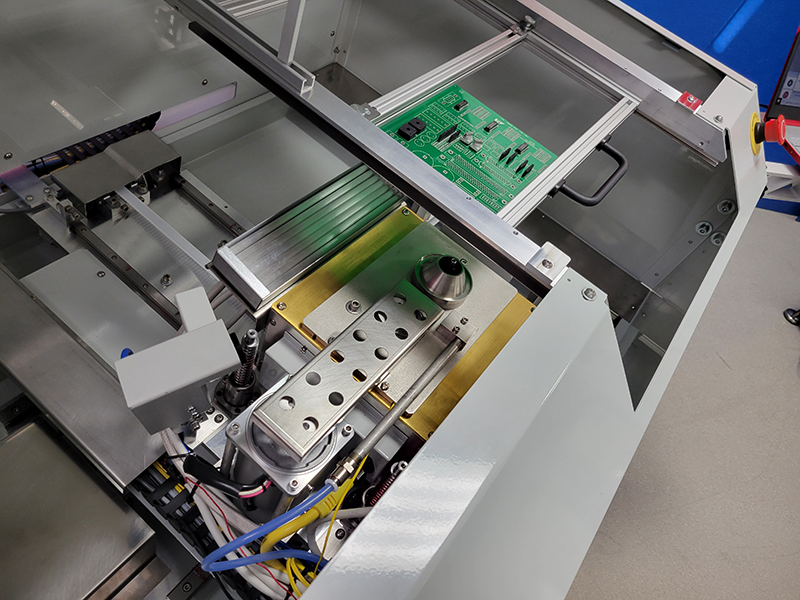

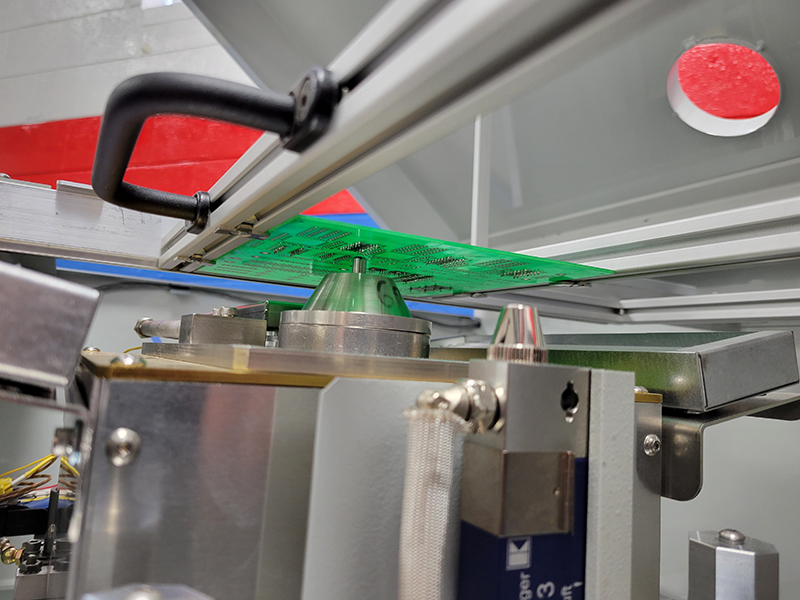

NS-13S (NovaSelect) Series

NovaSelect Series is an economical, compact selective solder system providing the convenience and flexibility of single point, drag, and mini-wave soldering. Ideal for low volume/high mix through hole soldering requirements, the system includes: Spray Fluxer, Bottom-side Preheat, and Lead/Lead Free Solder Pot, and is Nitrogen ready. Options include Topside Preheat, along with a wide assortment of nozzles.

Prototyping - Product Development - Short Run, High Mix Applications

- System includes: Spray Fluxer, Bottom-side Preheat & Lead/Lead Free Solder Pot with Nozzle.

- Through-hole soldering flexibility - single point, drag, mini-wave, or dip soldering.

Options

- Nitrogen Generator System

- Witness Camera Option

- Topside Pre-heat Option

- Custom Nozzles

- Custom Board Pallets

- Optional Stand

- Easy to use Windows based operating software

- Programming with Gerber Import

- Windows Laptop Included

- Topside Pre-Heat Option

- Witness Camera Option

- Wide Nozzle Assortment

- Nitrogen Ready (Nitrogen supplied by customer)

- Ease of Operation, small footprint, & durable construction

| Max board size | 330mm x 330mm (13" x 13") |

| Min. Neighbor Component Clearance | 1.5-3mm (0.06"-0.12") depending on nozzle size |

| Solder Capacity | Approximately 15 lbs. |

| Pressure (Nitrogen) | 2 bar (30 psi) |

| Flux System | Micro Spray |

| Warm up Time | 30 minutes |

| Max Temperature | 320°C (608°F) |

| Consumption (Nitrogen) | 0.8-1.7 CFM (23-49 liters/min) dependent on nozzle |

| Air Pressure | 5.5 bar (80 psi) |