Industries

Credit Card Manufacturing Company (CCMC) Application

(For customer privacy and security, we are using an alias for this article)

Many manufacturing companies come to us with similar major questions:

- “How do we choose the right SMT equipment company to work with?” and

- “How much customization to their standard pick & place system will be necessary to meet our requirements?”

In some cases, a full blown custom machine may be warranted; but often, working with an experienced and talented team of engineers like those at DDM Novastar, it will only involve creative modifications to a stock machine to accomplish the needed results, and save the buyer thousands of dollars.

CCMC (an actual but anonymous Credit Card Manufacturing Company), a global manufacturer of credit cards, came to DDM Novastar for a custom pick & place machine that would pick up a component to be used on each credit card, and place that component on a specific substrate.

CCMC was looking to create greater throughput and efficiency in their assembly process by moving from hand assembly to a more automated assembly process.

After thorough application and production review, it was mutually determined that DDM Novastar would provide CCMC with a fully automatic system incorporating a load and unload station, full conveyance (automatic conveyor), fully developed software package, and agreed-upon placement speeds/throughput capacity.

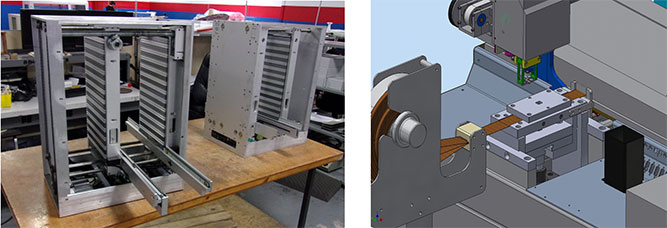

DDM Novastar’s engineering group created a fully automatic custom assembly system intended to integrate in-line with their manufacturing process. The DDM design included a load elevator, an unload elevator, an inline conveyor system, as well as the heart of system – the pick and place machine.

Challenges were minimal, since all of the functional specifications were well within DDM’s capabilities. The initial task was to design and manufacture the loader and unloader with uninterrupted loading, a small footprint, and SMEMA compatibility. The next stage was to adapt the inline conveyor system to allow component placement to meet designed placement speeds moving in a left-to-right transport direction.

These features were easily adaptable to their processes because of DDM’s parallel experience with similar automation techniques in the printed circuit board assembly markets.

DDM designed software that allows CCMC to data-log the number of placements completed per shift, the number of panel assemblies completed, and perform ‘lot tracing’, and ongoing production counts, during a 3 cycle (or 3 shift) workday.

The machine and software are integrated within a Cognex Vision system. This allows CCMC the ability to inspect the parts more thoroughly in the future for placement and fiducial recognition, or for any type of patterns they need to pick up.

Prior to delivery of the system, CCMC visited the factory for a trial run, and was so pleased with the process and results that they immediately ordered a second machine, with plans to purchase additional units in the future.

(Click here to see a short 3 minute simulated test run, prior to the setup of component placement.)